| Component |

Process Pictures |

Description |

| Tungsten Rods |

|

Each module contains 10,200

tungsten rods. These rods go through several processes before being

assembled into the module. The rods are incoming inspected, drilled,

pressure washed, hole QC'ed, ultrasonically cleaned, QC swabbed, the anode

pin is inserted, final wiping, and packaged. The rods are then stored in

the cleanroom where they will be wound with PEEK fibre, thermoformed, and

inserted into the module. |

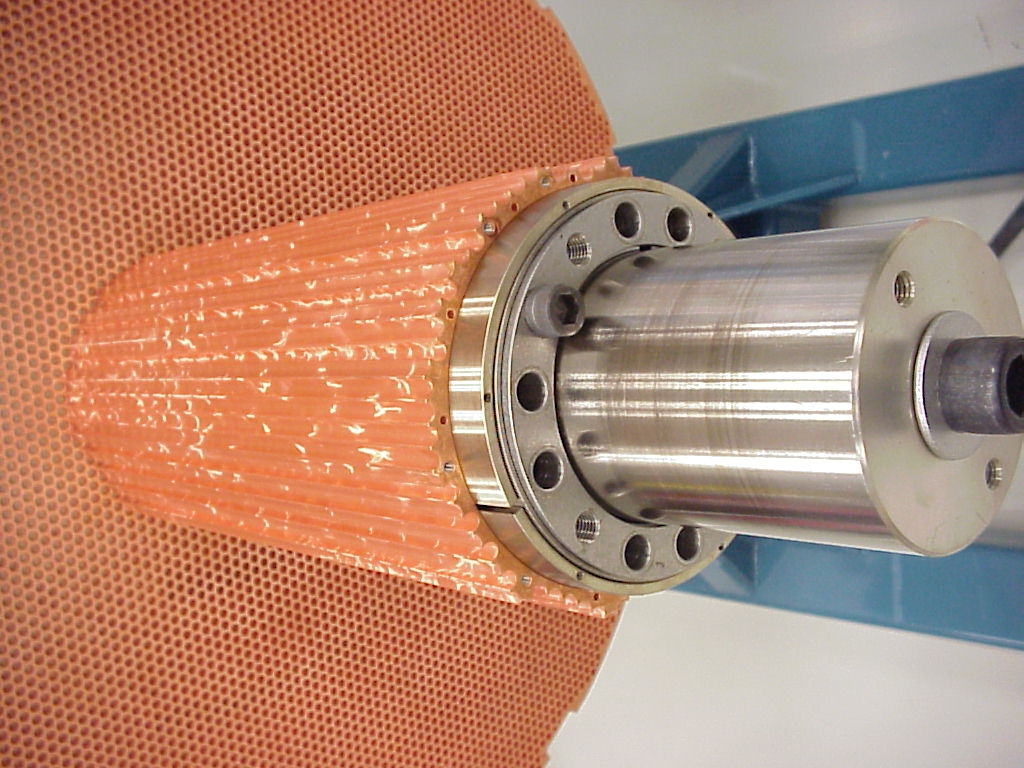

| Copper Tubes |

|

Each module contains 10,200

copper tubes. These tubes go through several processes before being

assembled into the module. The tubes are incoming inspected, deburred,

deburring QC'ed, pre-soaked in mineral spirits, swabbed out,

ultrasonically cleaned, QC swabbed, packaged and stored in the cleanroom. |

| Tungsten Slugs |

|

The sintered tungsten slugs are

QC inspected for length, profile, mass & density. The slugs are ultrasonically

washed, packaged and weighed, and then stored in the cleanroom. The slugs

are assembled into the module using the vibratory bowl "slug

feeder". Each module contains approximately 800,000 tungsten slugs |

|

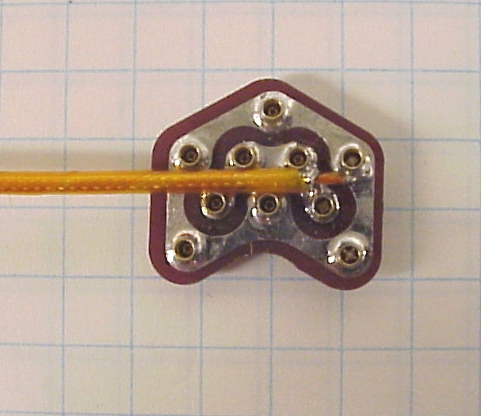

Copper Endplates

|

|

The module consists of two

copper endplates separated by the inner absorber. the copper tubes are

installed into the 10,200 electrode holes drilled into the endplates. The

tungsten slugs are stacked between the layers of the tubes. The endplates

were manufactured at the Science and Technology Centre at Carleton

University, Ottawa. |

| Inner Absorber |

|

The Inner Absorber forms the

inner form of the module. The curved surfaces correspond to the surface of

the inner layer of tubes and slugs. |

| Outer Absorbers |

|

|

| Interconnect Boards |

|

|